Consistent manufacturing system

Our company operates an in-house integrated response system from development to design and manufactur.

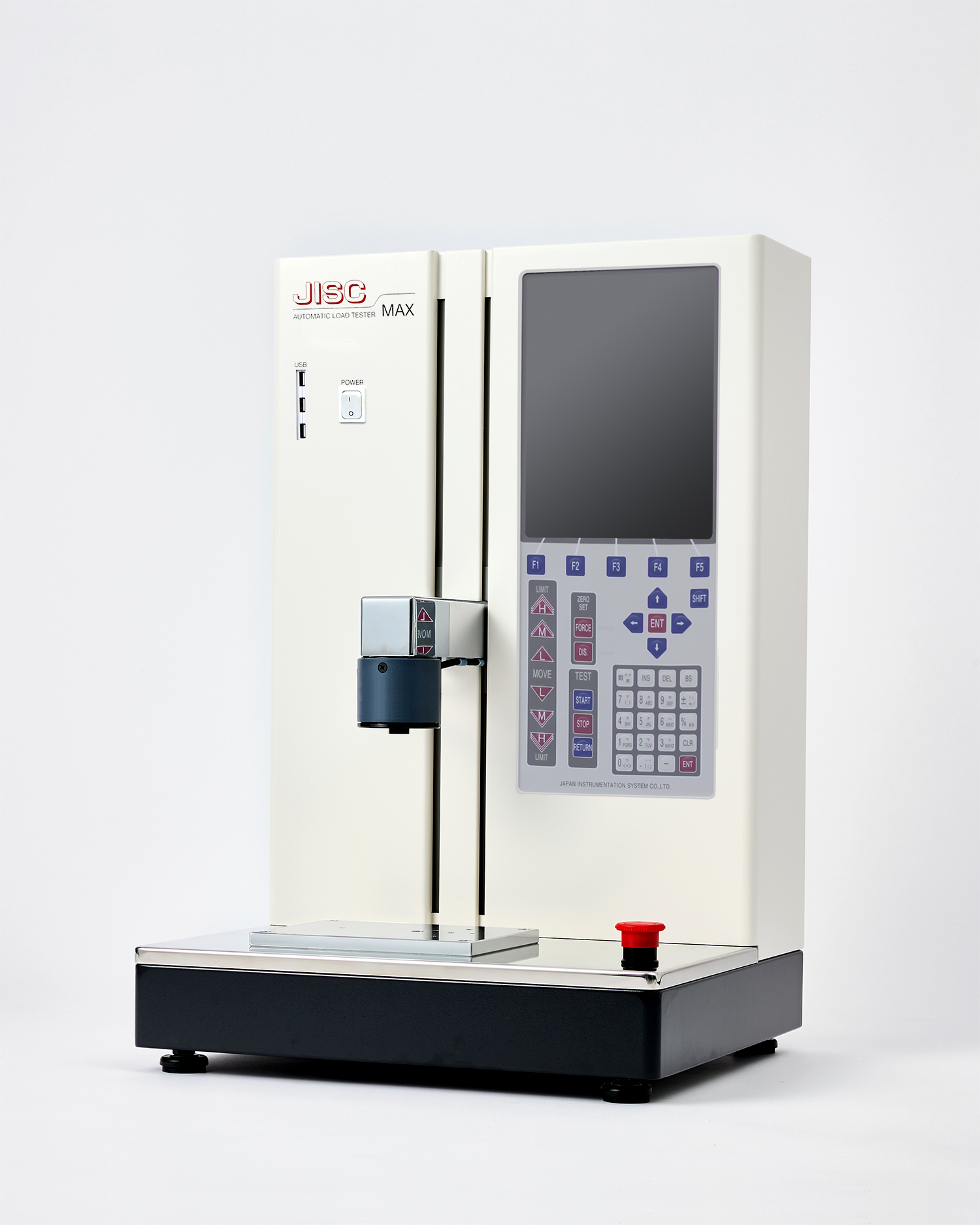

From the customer's point of view, we support society's 'manufacturing' with high-precision, user friendly testing equipment.

-

Development

The company develops its own testing equipment from hardware to software, including board and harness design and software programming.

-

Design

The testing machines are also designed in-house by ourselves, therefore it is also available for custom-designed, for example, when long stroke tests are required. Jigs and other component units are also designed in-house.

-

Manufacture

The manufacturing process is based on a strict checklist. The company also works closely with the Quality Assurance Department for interim inspections, etc., to ensure the manufacture of high quality products.

Quality Assurance (QMS)

A strict QMS has been established based on ISO 9001.

In addition to preventing the recurrence of equipment problems, improvements are solicited on daily and are systematically rooted in improvements that also take customer requirements into account.

Quality Policy

- Keep abreast of customer needs and provide quality products and services.

- Regular education and training to ensure the transfer of skills, fair and impartial calibration work, and overall skill development.

- Constantly strive to maintain and improve technical competency, safeguard the quality of exemplary professional work, testing, and calibration, and ensure high standards.

- Comply with laws, standards and regulations (requirements).

- Safeguard conformity with ISO 9001 and ISO/IEC 17025 and continuously improve the effectiveness of the QMS.

Product

Inspection

Calibration and Inspection

JIS B 7738 "Coil spring compression and tension testers" states that the period should not exceed 12 months, and verification should be carried out again after relocating.

We recommend inspection and calibration every 12 months, not only to maintain accuracy, but also to ensure safe and comfortable use for many years to come.

- On-site inspection and calibration

- Clear and easy-to-understand fee structure

- Use of traceable master equipment

- Inspection and calibration by educated and trained service engineers

- An Inspection certificate sticker (affixed to the testing machine) and a set of inspection certificates are issued

- Calibration and inspection of other manufacturers' testing equipment is also available, depending on the contents

Contents of calibration inspection and items to be specified

Contents of the complete set of inspection certificates issued after calibration and inspection

- Certificate Of Inspection

- Load inspection report

- Length inspection report

- Angle inspection report

- Inspection of correction function of deflection

- Traceability Chart

- Other Traceability Chart (at extra cost)

*Contents vary depending on the model.

JCSS calibration

We are accredited under the JCSS, which uses ISO/IEC 17025 (JIS Q 17025) as its accreditation standard. The JCSS (IAJapan) accreditation scheme is in accordance with ISO/IEC 17011, in collaboration with the Asia-Pacific Accreditation Cooperation (APAC) and International Laboratory Accreditation Cooperation (ILAC).

Our Calibration Department accreditation number is JCSS 0215, and it supports International MRA. JCSS calibration certificates can be issued in English.

For the latest information on JCSS calibration

Click here to go to the National Institute of Technology and Evaluation (NITE) page.